At MC Repairs, we cannot stress enough the importance of carrying out regular and correct maintenance procedures in your dental practice. A significant proportion of the handpieces we receive for repair have not been maintained in line with the manufacturer’s guidelines. This is not just a matter of best practice, it’s information that could save your dental practice thousands of pounds over time, as well as extend the lifespan of your equipment considerably.

What sets MC Repairs apart as your trusted small dental equipment partner is that our experienced technicians can quickly identify poor maintenance in handpieces. Whether it’s visible tidemarks, lack of lubrication, corrosion, or debris, the signs are often clear. Our mission is to support dental teams every step of the way aiding in reducing downtime, improving efficiency, and ensuring staff are confident in the correct handpiece care procedures.

Different Methods of Maintenance:

Every dental practice operates differently, and we understand that. Some teams use manual lubrication methods with compressed oil cans and high-speed adaptors, while others have automated oiling units in their decontamination rooms. Whichever system you use, MC Repairs can provide guidance to ensure that your handpieces undergo the correct maintenance and decontamination processes, in line with both manufacturer and infection-control standards.

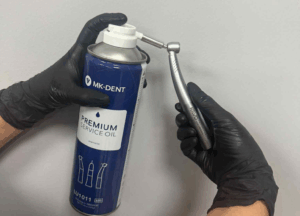

Manual Handpiece Lubrication:

Manual lubrication is a traditional yet highly effective method when performed correctly. It allows for hands-on control of the process, but it also leaves room for inconsistency if staff are not fully trained.

Our General Advice:

- Detach the handpiece from tubing, removing any bur.

- Don’t submerge the handpiece in any solution.

- Wipe away any external debris using a non-alcoholic approved disinfectant wipe.

- Using a dry tissue, remove any excess detergent leftover from the wipe.

- Ensure the correct highspeed adaptor is securely attached, shake the can well before attaching the handpiece.

- Spray the lubrication oil through the handpiece 2-3 seconds onto a clean tissue, hold the can upright.

- Check the colour of the expelled oil on the tissue, if the oil is discoloured, contact us immediately.

- Package the handpiece into a sterilisation pouch in accordance with applicable standards and follow sterilisation procedures.

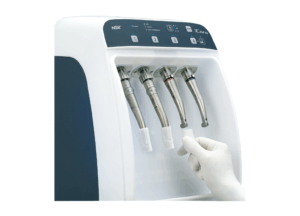

Oiling Unit Lubrication

An oiling unit automates the process, providing consistent lubrication and sometimes cleaning to clear debris. Some units require a 6 mm airline connection for operation, while others run solely on mains power.

Key Benefits:

- Ensures a consistent quantity of oil is delivered.

- Often includes built-in cleaning cycles.

- Reduces the likelihood of human error compared to manual lubrication.

Our Guide:

- Detach the handpiece from tubing, removing any bur. Don’t submerge the handpiece in any solution.

- Wipe away any external debris using a non-alcoholic approved disinfectant wipe. Using a dry tissue, remove any excess detergent leftover from the wipe.

- Select the appropriate adaptor for your handpiece models you’re lubricating.

- Connect the handpieces to the lubrication system, ensuring a tight fit to prevent leaks. Keep the handpiece head pointing towards the absorbent pads, if these aren’t available use a clean paper towel.

- Power on the lubrication system according to manufacturer’s instructions. Allow the lubrication system to run its cycle until completion.

- Wait until the system finishes before proceeding the next step. If you notice any discoloration, please contact us immediately.

- Package the handpiece into a sterilisation pouch in accordance with applicable standards and follow sterilisation procedures.

Importance of Frequent Maintenance:

Dental handpieces can be very delicate when considering the moving parts running at high speeds. Even a single missed lubrication can accelerate wear, reduce performance, and increase repair costs. By incorporating lubrication into your daily decontamination workflow, before and after every autoclave cycle you significantly improve reliability and patient safety also.

Regular maintenance also helps identify issues early. For example:

- Tidemarks may indicate moisture ingress.

- Rust may point to inadequate drying cycles.

- Unusual noise or vibration may mean internal bearings are wearing prematurely.

Sterilisation:

After lubrication, the sterilisation process must be carried out precisely.

- Always select the correct cycle for your specific handpiece type.

- Ensure your autoclave temperature does not exceed 138°C, as higher temperatures can damage delicate internal components.

- If your autoclave does not include a drying cycle, remove handpieces immediately once the sterilisation cycle finishes to avoid moisture-related damage.

Conclusion:

Proper handpiece maintenance cannot be seen as an optional extra, it’s a fundamental part of delivering safe, efficient, and cost-effective dental care. By adhering to manufacturer guidelines, using the correct lubrication methods, and staying vigilant for early signs of wear, your practice can extend the life of its equipment, reduce costly repairs, and maintain optimal performance for every patient.

At MC Repairs, we’re here to help you achieve that with our FREE Zoom Maintenance Calls, completely bespoke to your practice. Our team ensures your small dental equipment is always in top condition, keeping your practice running smoothly.

Please feel free to contact us if you have any further questions.

Contact Details:

01253 404 774

repairs@mcrepairs.co.uk

Other News

Why Choose MC Repairs?

Fully Accredited

We’re fully accredited and equipped for all small dental equipment repairs on brands such as Acteon, Anthogyr, Bien Air, DTE, EMS, KaVo, Mk-Dent, NSK, Star Dental, W&H, Woodpecker and much more!

OEM Quality Components

Where possible, we offer our customers only the best quality components, including longer warranties and ease of mind in manufacturers own parts so your equipment is as good as new!

State-of-the-Art Workshop

We don’t just say it, we actually mean it!

We’ve invested heavily into building our new state-of-the art workshop, adding much needed precision tooling and testing equipment.

Sustainable Repairs

Our dedication to environmentally responsible repairs has earned us ISO 14001 certification. Ensuring that our repair processes are fully efficient and eco-friendly.

Excellent Customer Service

Whether you order online or over the phone, our team are here to resolve any queries and deliver beyond dental practice’s expectations.

No Obligation, FREE Quotation

We adhere to our No Obligation, FREE Quotation allowing for in-depth analysis without any condition to pay unless you’re satisfied with the costs!